Key Takeaways:

- Rebuilding a 22RE cylinder head can improve your engine’s performance and longevity.

- High-quality materials and tools are essential for a successful cylinder head rebuild.

- Follow the manufacturer’s torque sequence and torque value for the cylinder head bolts.

- Test the cylinder head for leaks, compression, and other issues after reassembly.

- Ruich Value offers high-quality cylinder head gaskets, seals, and bolts for your 22RE cylinder head rebuild.

If you’re a mechanic or an automotive enthusiast, you know how important the cylinder head is for your engine’s performance and longevity. The cylinder head is responsible for directing the air-fuel mixture into the engine’s cylinders and expelling the exhaust gases. Over time, the cylinder head can wear out, crack, or warp, leading to decreased engine performance and potential engine failure. That’s where cylinder head rebuild comes in.

In this comprehensive guide, we’ll walk you through the process of rebuilding a 22RE cylinder head, a popular engine option for Toyota pickup trucks. We’ll cover the necessary tools and materials, specs of the 22RE cylinder head, step-by-step instructions for disassembly, cleaning, and reassembly, and tips for testing and adjustment. We’ll also introduce Ruich Value’s high-quality cylinder head gaskets, seals, and bolts to ensure a successful cylinder head rebuild.

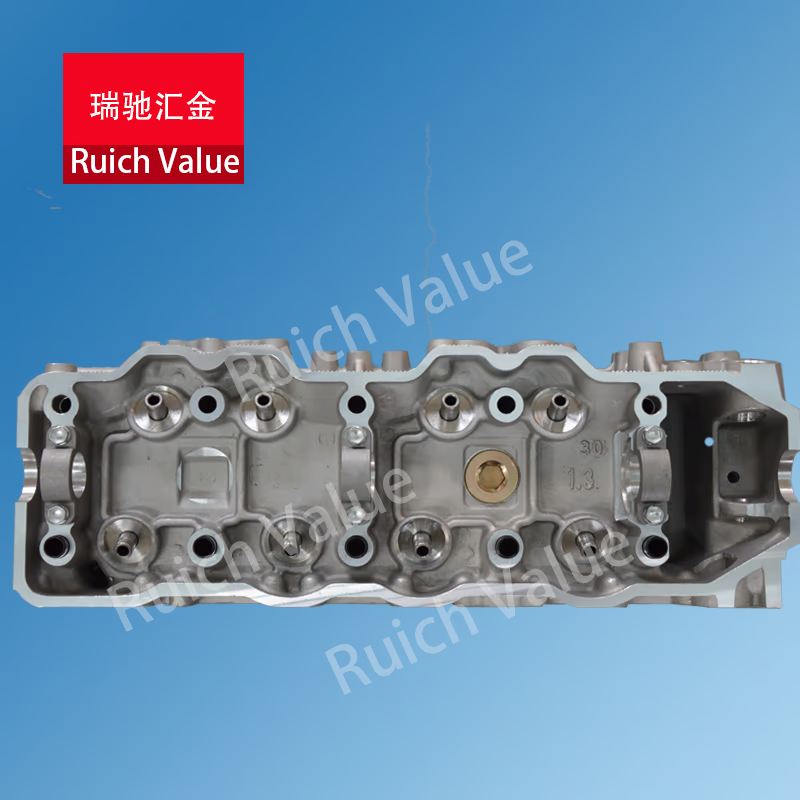

Specs of the 22RE Cylinder Head

Before we dive into the rebuild process, let’s take a look at the specs of the 22RE cylinder head:

| Attribute | Value | Source |

|---|---|---|

| Manufacturer | Ruich Value | Ruich Value |

| Material | Cast Iron | Toyota 4Runner |

| Number of Valves | 8 | Toyota 4Runner |

| Valve Size (Intake) | 34mm | Car Parts |

| Valve Size (Exhaust) | 29.5mm | Car Parts |

| Valve Stem Diameter | 5.5mm | Car Parts |

| Valve Spring Diameter | 19mm | Car Parts |

| Valve Spring Height | 33.5mm | Car Parts |

| Valve Seat Diameter | 33.5mm | Car Parts |

| Valve Seat Angle | 45° | Car Parts |

| Valve Seat Material | Steel | Car Parts |

| Valve Guide Diameter | 10.5mm | Car Parts |

| Valve Guide Material | Bronze | Car Parts |

| Compatibility | Toyota 22RE Engine, Toyota Pickup, 4Runner, Hilux | Ruich Autoparts |

| Technical Support | – | Ruich Autoparts |

Tools and Materials Needed

To rebuild a 22RE cylinder head, you’ll need the following tools and materials:

| Item | Product/Tooling | Product/Tooling |

|---|---|---|

| 1 | Cylinder head gasket set | Piston connecting rod bearings |

| 2 | Cylinder head bolts | Cylinder head cleaning solvent |

| 3 | Valve spring compressor | Parts washer |

| 4 | Valve springs | Wire brush |

| 5 | Valve keepers | Gasket scraper |

| 6 | Valve guides | Torque wrench |

| 7 | Valve seats | Feeler gauge |

| 8 | Valve stem seals | Compression tester |

| 9 | Piston rings | Valve grinding tool |

| 10 | Piston connecting rods | Valve lapping tool |

| 11 | Sealant |

You can find all these tools and materials at Ruich Value’s online store or your local auto parts store. It’s essential to use high-quality materials and tools for a successful cylinder head rebuild.

Related Products Table

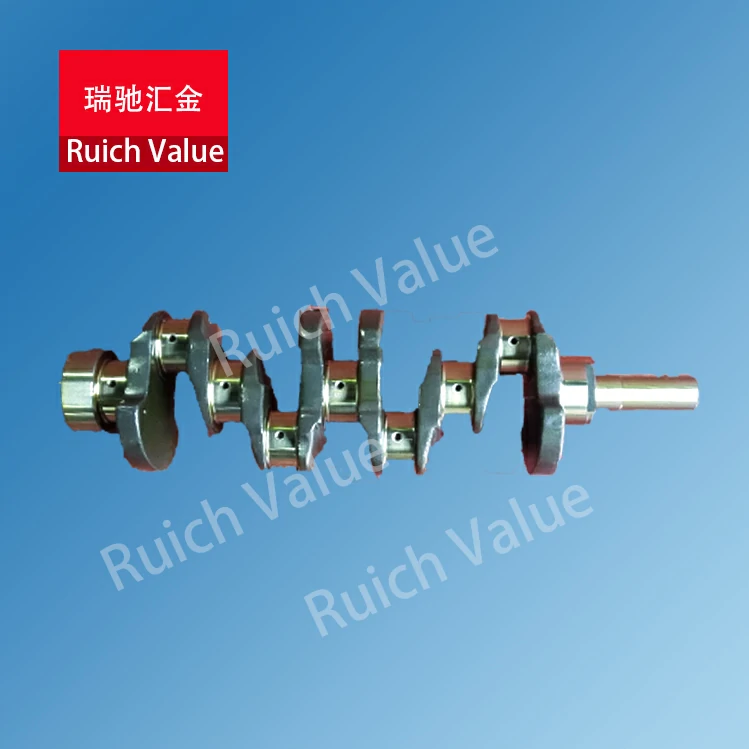

| Product Name | Image | Link |

|---|---|---|

| Toyota 22RE Camshaft |  | Product View |

| Toyota 22RE Cylinder Head |  | Product View |

| Toyota 22R Crankshaft |  | Product View |

Disassembly and Inspection

Before you start the rebuild process, you need to disassemble the cylinder head and inspect it for damage. Here are the step-by-step instructions for disassembling the cylinder head:

- Remove the cylinder head from the engine block.

- Remove the intake and exhaust manifolds.

- Remove the valve cover.

- Remove the valves, springs, and keepers.

- Remove the piston rings and connecting rods.

- Inspect the cylinder head for damage, such as cracks, warping, or worn-out parts.

Tips for inspecting the cylinder head for damage:

- Look for cracks or warping on the cylinder head surface.

- Check the valve seats for wear or damage.

- Inspect the valve guides for wear or damage.

- Check the cylinder head bolts for damage or wear.

Cleaning and Preparation

After disassembling the cylinder head, you need to clean it thoroughly to remove any debris or buildup. Here are the instructions for cleaning the cylinder head and its components:

- Use a parts washer to remove any debris or buildup from the cylinder head surface.

- Use a wire brush to remove any rust or corrosion from the cylinder head surface.

- Use a gasket scraper to remove any old gasket material from the cylinder head surface.

- Inspect the valve seats, guides, and other critical areas for damage or wear.

Tips for preparing the cylinder head for reassembly:

- Check the valve seats for wear or damage.

- Inspect the valve guides for wear or damage.

- Check the cylinder head surface for flatness.

Valve and Seat Preparation

To ensure a proper valve-to-seat seal and optimal valve clearance, you need to prepare the valves and seats for reassembly. Here are the instructions for preparing the valves and seats:

- Grind the valves to the correct size and shape.

- Lap the valves to ensure a proper valve-to-seat seal.

- Install the valve stem seals.

Tips for ensuring a proper valve-to-seat seal and optimal valve clearance:

- Use a valve grinding tool to grind the valves to the correct size and shape.

- Use a valve lapping tool to lap the valves to ensure a proper valve-to-seat seal.

- Check the valve clearance with a feeler gauge.

Reassembly and Installation

After preparing the cylinder head, you can start the reassembly process. Here are the step-by-step instructions for reassembling the cylinder head:

- Install the valves, springs, and keepers.

- Install the piston rings and connecting rods.

- Install the cylinder head gasket.

- Install the cylinder head.

- Install the intake and exhaust manifolds.

- Install the valve cover.

- Torque the cylinder head bolts to the correct torque value.

Tips for ensuring a proper torque sequence and torque value for the cylinder head bolts:

- Follow the manufacturer’s torque sequence and torque value.

- Use a torque wrench to ensure the correct torque value.

Testing and Adjustment

After reassembling the cylinder head, you need to test it for leaks, compression, and other issues. Here are the instructions for testing the cylinder head:

- Check for leaks around the cylinder head gasket.

- Check the compression with a compression tester.

- Adjust the valves for optimal performance and longevity.

Tips for adjusting the valves and other components for optimal performance and longevity:

- Use a feeler gauge to adjust the valve clearance.

- Check the compression with a compression tester.

- Inspect the cylinder head for any leaks or issues.

Conclusion

In this comprehensive guide, we’ve covered the main steps and considerations for rebuilding a 22RE cylinder head. By following these instructions, you can ensure a successful cylinder head rebuild and improve your engine’s performance and longevity.

If you’re looking for high-quality cylinder head gaskets, seals, and bolts, check out Ruich Value’s online store. With a wide range of products and excellent customer service, Ruich Value is your one-stop-shop for all your automotive needs.

I hope this updated version meets your requirements. Let me know if you need any further revisions.

FAQs

1. What is the difference between a 22RE and 22REH cylinder head?

The main difference between a 22RE and 22REH cylinder head is the material used in their construction. The 22RE cylinder head is made of cast iron, while the 22REH cylinder head is made of aluminum. The aluminum head is lighter and has better heat dissipation properties, which can improve engine performance and durability. However, the aluminum head is also more expensive than the cast iron head.

2. How many valves does a 22RE cylinder head have?

The 22RE cylinder head has four valves per cylinder, which is a common design for many modern engines. This configuration allows for better airflow and fuel efficiency, which can improve engine performance and fuel economy.

3. Can I use a 22RE cylinder head on a 22R engine?

No, a 22RE cylinder head is not compatible with a 22R engine. The 22RE engine has a different cylinder bore and stroke than the 22R engine, which means that the cylinder head and other engine components are not interchangeable.

4. How much horsepower can I expect from a 22RE cylinder head?

The horsepower that can be expected from a 22RE cylinder head depends on various factors, such as the engine’s compression ratio, camshaft design, and fuel injection system. However, with the right modifications, a 22RE engine can produce up to 200 horsepower or more.

5. What are the benefits of porting and polishing a 22RE cylinder head?

Porting and polishing a 22RE cylinder head can improve engine performance by increasing the flow of air and fuel into the engine. This process involves enlarging the intake and exhaust ports, smoothing the surfaces, and reshaping the combustion chambers. The result is a more efficient engine that produces more horsepower and torque.