Currently, Most of the traditional camshafts are produced by casting or forging, and some are also manufactured with carbon steel.

Cast camshafts mainly include chilled cast iron, quenched cast iron, etc. To save weight, some camshafts are core cast, making the shaft hollow. Chilled cast iron camshafts are mainly used in Japan, and hardened cast iron camshafts are mainly used in the United States. In order to improve the performance of the engine, various camshafts developed such as remelted chilled cast iron and ductile iron have been developed in recent years, but their application scope is limited to a few fields due to their cost and application fields;

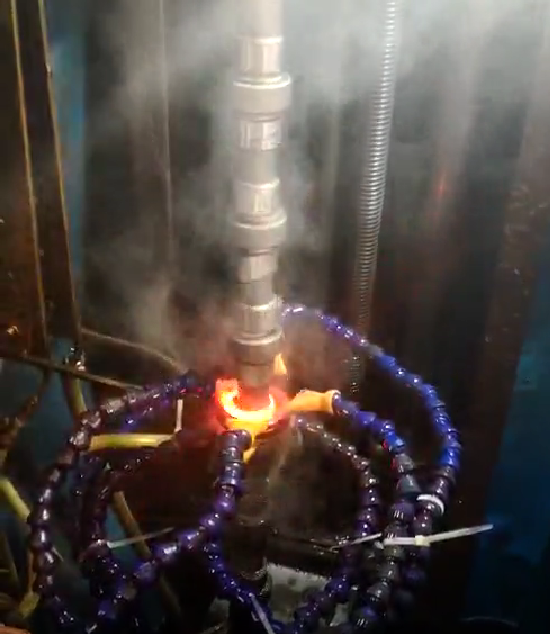

The forged camshaft is mainly made of carbon steel for hot forging, and the cam is processed by high-frequency quenching, which is mainly used in large and medium-sized engines. Because of its good corrosion resistance, it is mostly used in combination with the tappet of the overhead valve (OHV), and it is also used in conjunction with the rocker arm in the upper cam (OHC) structure of the diesel engine. Since forged camshafts cannot be lightweight, the development Potentiality is limited. it is difficult to ensure the different performance requirements of the engine valve train for various parts of the camshaft due to the traditional camshafts manufacturing characteristics. The arrangement of the cams cannot be very compact, the material utilization is not reasonable, and the follow-up manufacture processing is complicated. New breakthroughs are hard to be achieved

Metal-plastic composite camshafts have been introduced. The powder metal cam edge and hollow steel shaft are placed into a mold, and plastic is injected cover the hollow shaft. There is no direct contact between the cam plate and the shaft, but is fixed by plastic to became a whole shaft. The cost and weight of this camshaft can be reduced by 40%, the engine noise can be reduced, and the processing preparation time can be shortened from the few hours to minutes

The assembly camshaft is currently developing with a fast speed and is mainly used in high-performance engines. At present, more and more assembly camshaft are used in auto companies. But its kindness are quite different from each other due to production technology and manufacturing process.