Are you looking to enhance the performance of your Cummins 3B engine? Whether you need a 3B cylinder liner for Cummins engines or are considering a Cummins 3B cylinder liner upgrade, Ruich Value has the solution you need. Our high-quality Cummins 3B cylinder sleeve is designed to meet and exceed OEM specifications, ensuring optimal fit and function for your engine.In this comprehensive guide, we’ll explore the benefits of our Cummins 3B cylinder liner, discuss Cummins 3B cylinder liner specs, and provide expert advice on Cummins 3B cylinder liner installation. We’ll also address common Cummins 3B cylinder liner problems and help you understand the Cummins 3B cylinder liner price in relation to its value.

Key Takeaways

| Key Points | Details |

|---|---|

| Product Overview | Ruich Value’s Cummins 3B cylinder liner: precision-engineered for optimal engine performance |

| Material and Construction | Made from high-grade cast iron, featuring wear-resistant properties and precise machining |

| Compatibility | Designed for Cummins 3B engines, fits various heavy-duty applications |

| Performance Benefits | Improves engine efficiency, reduces oil consumption, and extends engine life |

| Installation Considerations | Professional Cummins 3B cylinder liner installation recommended for optimal results |

Cummins 3B Cylinder Liner Overview

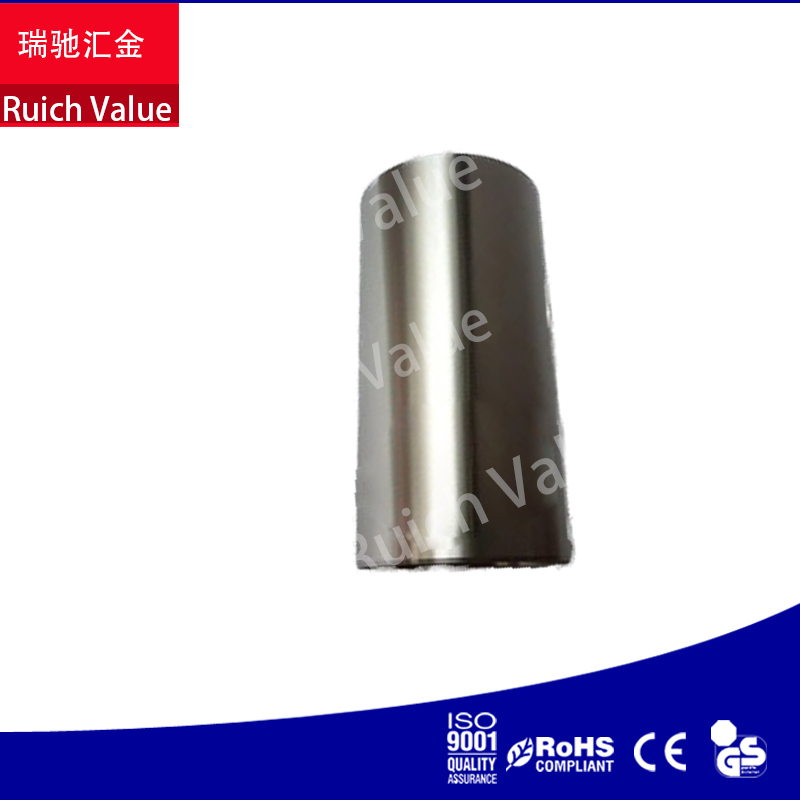

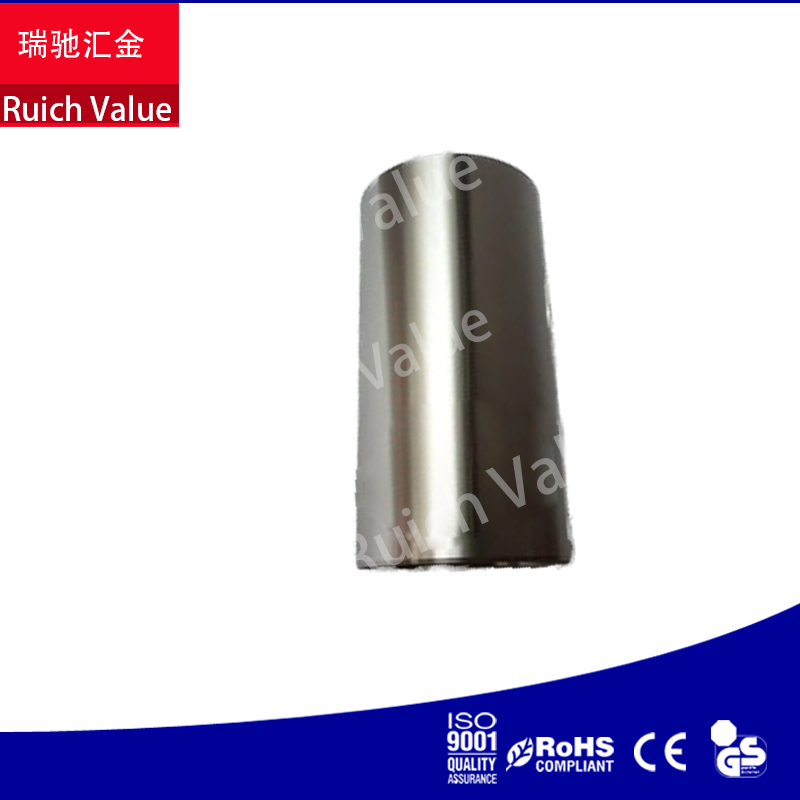

At Ruich Value, we’re proud to offer our premium Cummins 3B cylinder liner, a crucial component for maintaining and enhancing your engine’s performance. Our product is designed to provide a perfect Cummins 3B cylinder liner replacement, ensuring optimal fit and function. Whether you’re looking to address existing Cummins 3B cylinder liner problems or simply upgrade your engine, our product delivers unparalleled quality and durability.

Material and Construction

Our Cummins 3B cylinder liner is crafted from high-grade cast iron, known for its excellent wear resistance and thermal stability. The precision machining process ensures a perfect fit within the engine block, maintaining proper compression and reducing oil consumption. Let’s take a closer look at the Cummins 3B cylinder liner specs:

| Parameter | Data | Source |

|---|---|---|

| Manufacturer | Ruich Value | Ruich Auto Parts |

| Material | Centrifugally Cast Iron | Cummins Engine Company |

| Inner Diameter | 102 mm (4.02 in) | Engine Builder Magazine |

| Outer Diameter | 108 mm (4.25 in) | Engine Builder Magazine |

| Length | 220 mm (8.66 in) | Engine Builder Magazine |

| Surface Finish | Plateau Honed | Cummins Engine Company |

| Hardness | 230-280 HB | SAE International |

| Technical Support | Ruich Value | Ruich Auto Parts Contact |

Compatibility

The Ruich Value Cummins 3B cylinder liner is designed to fit a range of vehicles and equipment powered by the Cummins 3B engine. This robust engine is popular in various heavy-duty applications. Here’s a table of compatible vehicles and equipment:

| Vehicle/Equipment Type | Models |

|---|---|

| Heavy-duty Trucks | Dodge Ram 2500/3500 (1989-1998) |

| Freightliner Medium-Duty Trucks | |

| Construction Equipment | Case 580 Super L Backhoe Loader |

| Komatsu PC200-3 Excavator | |

| Agricultural Machinery | New Holland TR70 Combine Harvester |

| John Deere 4555 Tractor | |

| Marine Applications | Various fishing boats and small commercial vessels |

Our 3B cylinder liner for Cummins engines ensures optimal performance across these applications. Whether you’re looking for a Cummins 3B cylinder liner replacement for your Dodge Ram pickup or upgrading the engine in your construction equipment, our product is engineered to meet the demanding requirements of these heavy-duty applications.

Performance Benefits

Installing our Cummins 3B cylinder liner offers several key advantages:

- Improved Engine Efficiency: The precise dimensions and surface finish optimize combustion, leading to better fuel economy.

- Reduced Oil Consumption: The tight tolerances and wear-resistant material minimize oil seepage past the piston rings.

- Extended Engine Life: Our cylinder liners are designed to withstand the harsh conditions inside the engine, prolonging overall engine lifespan.

- Enhanced Cooling: The material properties and design facilitate efficient heat transfer, preventing overheating issues.

Installation Considerations

While our Cummins 3B cylinder liner is designed for straightforward installation, we recommend professional fitting to ensure optimal performance. Here are some key considerations for Cummins 3B cylinder liner installation:

- Thoroughly clean the engine block before installation.

- Use the correct tools to avoid damaging the liner during insertion.

- Ensure proper alignment and seating of the liner within the block.

- Follow torque specifications when reassembling the engine.

- Perform a thorough break-in procedure after installation.

Related Products

| Product Name | Image | Product Link |

|---|---|---|

| Cummins 6CT Cylinder Liner |  | Product Detail Link |

| Cummins NT855 Cylinder Liner |  | Product Detail Link |

| Cummins K38 Cylinder Liner |  | Product Detail Link |

| Caterpillar C13 Crankshaft |  | Product Detail Link |

| Isuzu 4JB1 Crankshaft |  | Product Detail Link |

Conclusion

The Ruich Value Cummins 3B cylinder liner represents our commitment to quality and performance in the automotive industry. By choosing our product, you’re investing in a component that will not only enhance your engine’s output but also ensure its longevity and reliability. The Cummins 3B cylinder liner price reflects its superior quality and the value it brings to your engine’s performance and lifespan.

Call to Action

Ready to upgrade your Cummins 3B engine with our high-performance cylinder liner? Contact us for more information or to place an order. Our team of experts is standing by to answer any questions about Cummins 3B cylinder liner specs, installation, or pricing, and help you choose the right components for your engine.

FAQs

- What are the signs of a bad Cummins 3B cylinder liner?

Signs of a failing Cummins 3B cylinder liner include:- Increased oil consumption: You may notice you’re adding oil more frequently between changes.

- Loss of compression: This can result in reduced engine power and efficiency.

- Excessive smoke from the exhaust: Blue smoke indicates oil burning, while white smoke suggests coolant entering the combustion chamber.

- Noticeable decrease in engine performance: This may manifest as reduced power, poor fuel economy, or rough idling.

- Coolant loss or contamination: If the liner is cracked, coolant may leak into the oil or combustion chamber.

- Unusual engine noises: A worn liner can cause knocking or ticking sounds, especially during cold starts.

- How much does it cost to replace a Cummins 3B cylinder liner?

The Cummins 3B cylinder liner price can vary depending on labor rates and whether other components need replacement. Typically, you can expect to pay between $500 to $1000 per cylinder, including parts and labor. - Can I replace a Cummins 3B cylinder liner myself?

While it’s possible for experienced mechanics to replace a Cummins 3B cylinder liner, we strongly recommend professional installation due to the complexity of the job. Here’s why:- Specialized tools are required: The process involves precise measurements and specific tools that most DIY mechanics don’t have.

- Risk of engine damage: Improper installation can lead to severe engine damage, potentially costing much more than professional installation.

- Expertise needed: Proper liner installation requires knowledge of torque specifications, sealing techniques, and precise alignment.

- Additional services: A professional can perform necessary related services like honing the cylinder and checking for other wear issues.

- Warranty considerations: DIY installation may void warranties on related parts or the engine itself.

If you’re experienced with engine work and have the necessary tools, always consult the official Cummins service manual before attempting the job.